Flamingo

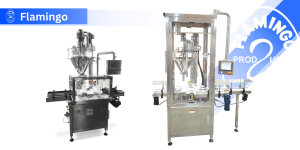

Flamingo Fully Automatic Powder Filling Lines

Streamline Your Production with Flamingo Powder Filling Machines

The Flamingo Fully Automatic Powder Filling and Capping Lines, engineered for efficiency and versatility in powder filling applications. Our automatic powder filling machines are designed to meet a wide range of filling requirements, ensuring precise and consistent performance across various industries.

Ready to elevate your production line with Flamingo Fully Automatic Powder Filling and Capping Lines? Contact us today for pricing and to discuss your specific requirements. Our expert team is here to assist you in finding the perfect solution tailored to your needs.

*Contact Us for Pricing and Further Information

Discover Our Flamingo Machines

Key Benefits and Advantages

- Increased Efficiency: Automating the filling and capping processes significantly reduces labor costs and improves overall productivity.

- Precision and Consistency: Our advanced technology ensures accurate filling and capping, minimizing product waste and enhancing quality control.

- Flexible Production Capabilities: Easily switch between different products and package sizes with our machines, allowing you to adapt quickly to changing market demands.

- User-Friendly Interface: Designed for ease of use, our machines feature intuitive controls that simplify operation and reduce training time.

- Durable and Reliable: Built with high-quality materials, Flamingo machines are designed for longevity and consistent performance, even in high-demand environments.

Features

- Customizable Head Configurations: Choose from one to four filling heads, allowing you to scale your production capacity based on your needs.

- Advanced Auger Design: Our state-of-the-art auger fillers are suitable for different volumes and ensure optimal flow control, accommodating various powder characteristics.

- Versatile Filling Mechanisms: Our machines utilize augers to accurately fill a wide range of powders and granules, ensuring precise volume or weight delivery for your products.

- Wide Range of Product Compatibility: Capable of handling powders with varying densities and volumes from 10 grams to 5 kg, making them ideal for applications in food, beverage, pharmaceuticals, cosmetics, and chemicals.

- In-Line or Rotary Fillers: The Flamingo Powder Fillers can be configured as in-line or rotary systems, allowing flexibility to fit your production layout.

- Container Feed and Collection Turn Tables: Featuring stainless steel construction and variable speed options, our turn tables are available in sizes from 800mm to 1200mm, enhancing the efficiency of your production line.

- Automated Capping Systems: Our fully automatic capping systems are tailored to fit specific cap designs, enhancing production speed and reliability. The Flamingo cappers include both 4-wheel and chuck capping options.

- Ancillary Equipment: Complete your production line with optional ancillary equipment like carton erectors, carton tapers, and printers for a fully integrated packaging solution.

PHONE

+612 9427 3270

Sales@Fleming.com.au

ADDRESS

7/27 Mars Rd, Lane Cove West,

Sydney NSW 2066 Australia

Operating Hour

09:00 AM – 16:30 PM

Feel Free To Contact Us Anytime

We typically respond within 24 hours.