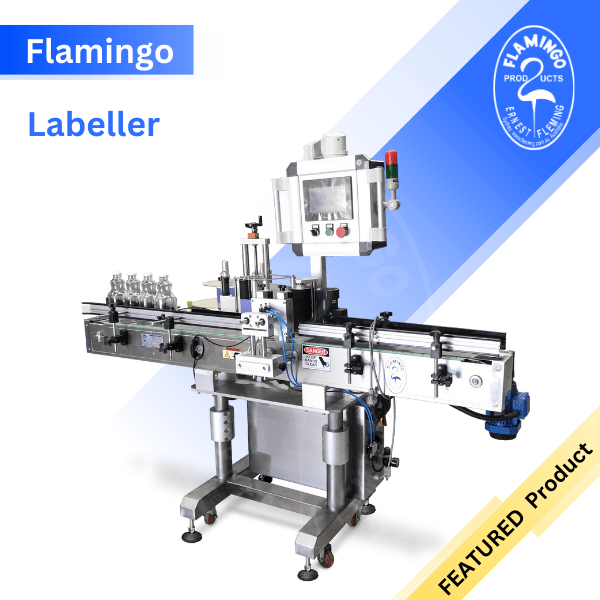

Flamingo

Auto Wrap-Around Clamp Labeller

is a fully automatic labeling solution designed for applying precision wrap-around labels on round containers and bottles.

*Contact us for Pricing

Discover Our Flamingo Machines

Overview

The Flamingo Automatic Wrap-Around Clamp Labeller is a fully automatic labeling solution designed for applying precision wrap-around labels on round containers and bottles. Ideal for a variety of industries, including food and beverage, pharmaceuticals, and cosmetics, this labeller ensures consistent, professional-quality labeling with ease.

* Contact Us for Pricing and Further Information

Key Benefits and Advantages

- High-Precision Label Application:

Equipped with a servo-motor-driven label application head, the Labeller guarantees accurate label positioning, ensuring every label is applied perfectly every time. - Versatile Labeling Options:

Capable of applying both partial and full wrap-around labels, this machine handles pressure-sensitive (self-adhesive) labels, accommodating a wide range of cylindrical containers including plastic, metal, glass, and composite materials. - User-Friendly Operation:

Designed for simplicity, the Labeller allows for easy bottle and label set-up, making changeovers quick and efficient, which is essential for dynamic production environments.

A Complete Labelling Solution

- Integrated Container Separation Module:

Features an adjustable module that ensures precise bottle timing, optimizing the labeling process for high throughput. - Advanced Sensing Technology:

Equipped with optical sensors, the Labeller efficiently detects both opaque and printed labels, ensuring accurate application on various surfaces. - MITSUBISHI PLC and Touchscreen HMI:

The intuitive control system provides easy navigation and adjustments, enhancing operational efficiency. - Speed-Adjustable Wrap-Around Module:

This feature allows for 360° perimeter application, accommodating various container sizes and shapes. - Durable Construction:

Made with a stainless steel and anodized aluminum body, the Labeller is built to withstand rigorous use while ensuring long-term reliability. - Stable Container Movement:

The machine includes a 2.4-meter speed-adjustable conveyor with a rust-proof plastic flat-top chain, ensuring smooth and stable movement of containers through the labeling process. - Adjustable Guide Rails:

Easily adjustable guide rails enhance setup flexibility for different container sizes. - Remote Machine Status Monitoring:

Equipped with dual-color light signals, operators can easily monitor machine status from a distance.

Custom Solutions Available

We also offer custom specialized application labellers tailored to meet your unique production requirements. Please inquire for more details.

Additional information

| Label Width | 10-150 mm |

|---|---|

| Label Length | 10-200 mm |

| Labelling Speed | Up to 6000 bottles/hour |

| Labelling Accuracy | ±1 mm |

| Bottle Diameter | Up to 100 mm |

| Power Source | 450W, 220V, 50Hz/60Hz |

| Label Reel Inner Diameter | 75 mm |

| Label Reel Outer Diameter | 360 mm |

| Weight | 80 kg |

| Dimensions | 1200×800×550mm |

| Control System | Japanese Mitsubishi PLC |

PHONE

+612 9427 3270

Sales@Fleming.com.au

ADDRESS

7/27 Mars Rd, Lane Cove West,

Sydney NSW 2066 Australia

Operating Hour

09:00 AM – 16:30 PM

Feel Free To Contact Us Anytime

We typically respond within 24 hours.