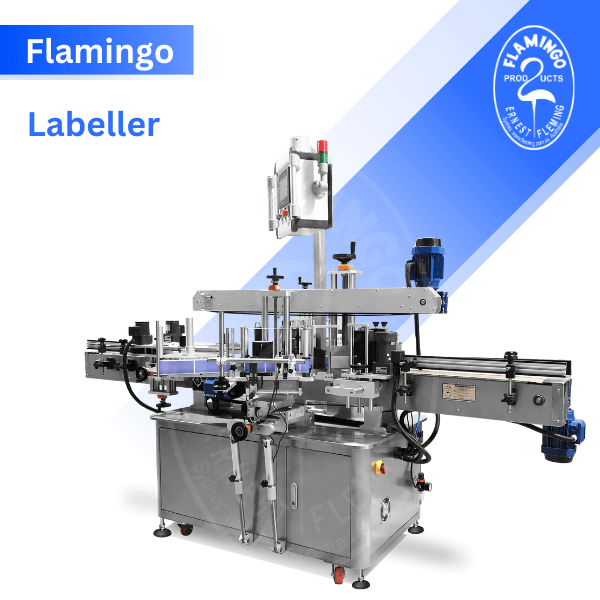

Flamingo

2-Side Wrap-Around Index Labeller

is a cutting-edge labeling machine designed for versatility and efficiency.

*Contact us for Pricing

Discover Our Flamingo Machines

Custom Solutions

The Flamingo Multi-Functional 2 Side Wrap-Around Index Labeller is a cutting-edge labeling machine designed for versatility and efficiency. Ideal for use in the pharmaceuticals, daily chemicals, food, and beverages industries, this labeller provides automatic labeling solutions for various container shapes, including round, oval, and flat.

* Contact Us for Pricing and Further Information

Key Benefits and Advantages

- Automatic Label Detection:

The Labeller automatically detects label size and bottle diameter, adjusting labeling parameters to ensure optimal performance. This feature is especially beneficial for users managing multiple products. - Versatile Labeling Capability:

This machine can apply one or two pressure-sensitive (self-adhesive) labels, with options for partial and wraparound labeling, accommodating a wide range of container types. - High Performance:

Capable of labeling at speeds of 60 to 180 labels per minute (depending on label length), the Labeller combines speed and accuracy to enhance production efficiency. - Robust Container Handling:

Equipped with a 2.2-meter long speed-adjustable conveyor and a synchronized container top conveyor, the machine ensures stability by gripping the crown of the container during labeling. - Customizable Options:

The Labeller supports various label dimensions, with a maximum label length of 300mm and a maximum height of 150mm. It can accommodate container diameters ranging from 20mm to 150mm and heights up to 400mm. - Reliable Engineering:

Backed by a strong engineering team, the Labeller is designed and programmed in Australia, ensuring compliance with GMP standards and long-term reliability.

Feature

- Enhanced Flexibility:

The ability to label different container shapes and sizes makes the Labeller a versatile addition to any production line. - User-Friendly Operation:

The Flamingo Design Easy Operate HMI, programmed in-house, provides an intuitive interface for easy operation and quick adjustments. - Precision and Accuracy:

With labeling accuracy of ±1mm, this labeller delivers professional results, enhancing product presentation and customer satisfaction. - Durable Construction:

Built with high-quality materials, the Labeller is designed for durability, featuring rust-proof components for long-term use. - Custom Solutions Available:

Tailored solutions can be provided to meet unique production needs, ensuring optimal performance for your specific application.

Additional information

| Label Width | 10-150 mm |

|---|---|

| Label Length | 10-300 mm |

| Labelling Speed | Up to 6000 bottles/hour |

| Labelling Accuracy | ±1 mm |

| Bottle Diameter | 20 – 180 mm |

| Maximum Bottle Height | 400 mm |

| Power Source | 450W, 380V, 50Hz/60Hz |

| Label Reel Inner Diameter | 75 mm |

| Label Reel Outer Diameter | 360 mm |

| Weight | – |

| Dimensions | – |

| Control System | Japanese Mitsubishi PLC |

- Hot Stamp Printing Coder: Prints characters directly onto the label.

- Fully Integrated Inkjet Printing Coder: Prints characters directly onto the label or container.

- Clear Label Luize Sensors: Capable of detecting transparent labels.

PHONE

+612 9427 3270

Sales@Fleming.com.au

ADDRESS

7/27 Mars Rd, Lane Cove West,

Sydney NSW 2066 Australia

Operating Hour

09:00 AM – 16:30 PM

Feel Free To Contact Us Anytime

We typically respond within 24 hours.